What began in May 1946 as a small repair shop for rubber articles in war-ravaged Kassel has developed over the decades into a true global player in the mobility industry: With approximately 3,500 employees at more than 30 locations, the HÜBNER Group is now a world leader in the field of gangway systems as well as elastomer seals for buses and trains.

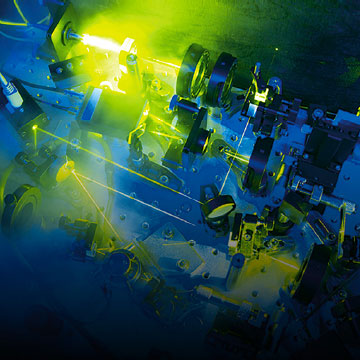

In addition, the HÜBNER Group also supplies chassis systems, cockpit displays, folding canopies for passenger boarding bridges, coated textiles for biogas systems and GRP hoods for construction vehicles. And for several years, high-performance lasers have also been part of the company's product portfolio. The anniversary is being celebrated under the motto: "HÜBNER connects. People. Products. Places."

#75yearsHUEBNER

Please click previewimage to start video (privacy-policy).

How it all began: The beginnings of the HÜBNER business segments

The story of the HÜBNER Group starts in the year 1946. In the challenging post-war period, Kurt Hübner founds a company for rubber articles and repairs. The workshop quickly established itself as a specialist for rubber production and as the regional expert for special developments in the field.

Interview with Helge Förster, Ingolf Cedra and Gerald Steinhoff – HÜBNER's General Management

A technology leader – with a strong tradition and a forward-looking vision

In the following interview, HÜBNER's three general managers Helge Förster (Mobility), Ingolf Cedra (Materials & Photonics), and Gerald Steinhoff (Corporate Functions) talk about how the company is meeting current challenges, the solutions it is working on, and what will make HÜBNER successful in the future.

Thinking globally, acting locally

HÜBNER worldwide

Reinhard Hübner established the first subsidiary of the company in 1979 in Brazil. When the company passed to him from his father Kurt Hübner, he set about developing the company further together with his general managers. As the company grew, new production capacities were needed. To meet the large demand for gangway systems, HÜBNER established another international location in Charleston, South Carolina in the USA.

And further production sites followed – in Hungary, Russia and in China, which in the meantime has become the largest rail market in the world. In subsequent years there were also new branches established in Sweden, France, Italy, India and many other places. Today the HÜBNER Group has 30 locations around the world.

The history of the HÜBNER Group

Milestones of company history

The story of the HÜBNER Group begins in the year 1946. In the post-war period, 40-year-old Kurt Hübner founds a company for rubber articles and repairs. The company quickly established itself as a specialist for rubber production and as the regional expert for special developments in the field. Over the course of time, the company brings numerous new products to the market which quickly come to set benchmarks for various industries – from folding bellows to tunable lasers. Today the products of HÜBNER are in daily use all around the world.

Please click previewimage to start video (privacy-policy).