The HÜBNER business segment Material Solutions is the specialist for sophisticated solutions featuring elastomers, polyurethane as well as industrial textiles. Our focus is on innovative, technically challenging products for high-growth markets such as building and construction, aerospace, healthcare as well as the mobility sector.

At the same time, we offer the economical and versatile fiber composite FRP (fiber-reinforced plastic) as well as innovative products for the insulation of buses and trains and for building and industrial applications. Last but not least, we are the main supplier of the HÜBNER Mobility business segment, providing products and solutions that conform with the demanding fire-safety requirements specified by EN standards for the transportation sector.

The HÜBNER business segment Material Solutions is the specialist for sophisticated solutions featuring elastomers, polyurethane as well as insulation components and industrial textiles. Our focus is on innovative, technically challenging products for high-growth markets such as building and construction, aerospace, healthcare as well as the mobility sector.

At the same time, we offer the economical and versatile fiber composite FRP (fiber-reinforced plastic) as well as innovative products for the insulation of buses and trains and for building and industrial applications. Last but not least, we are the main supplier of the HÜBNER Mobility business segment, providing products and solutions that conform with the demanding fire-safety requirements specified by EN standards for the transportation sector.

Elastomer-Lösungen

Elastic and resilient

HÜBNER got its start with the repair of conveyor belts and rubber components. Today the company produces a wide ranging spectrum of rubber and silicone products – from mini-components to seals weighing several kilograms. What makes the elastomers rubber and silicone so special? As industrially processed materials they display both elasticity and shape retention.

Elastomer solutions from HÜBNER are used in different industries around the world. For railway vehicles and other vehicles, the company produces window sealing systems, door profiles and finger protection profiles with integrated sensors. Products in the medical technology sector include silicone membranes for dialysis machines. Our products for the oil industry are particularly robust – they can withstand the extreme weather conditions in offshore settings as well as high pressure applications and contact with oil.

HÜBNER also has many years of experience in the defense technology sector. The company produces diving seals and other rubber products that are resistant to chemical and biological agents. Docking fenders and rub strakes for boats are also part of the product portfolio. HÜBNER provides individual elastomer solutions as required by the customer – manufactured as extruded, fabricated or molded parts. The company's development department has decades of experience and more than 600 recipes for rubber compounds that it brings to each new project.

The expert staff make use of the latest software such as SAP or CATIA as well as in-house toolmaking capacities. With these resources, the company produces molded and extrusions parts, injection-molded corners, rubber-metal and silicone-metal bonded components all in the highest quality. A full range of standard material testing – including for fire-safety requirements – is conducted in the company's own research laboratories by highly trained specialists.

Discover our Material Solutions for Industry and Rail & Bus.

HÜBNER got its start with the repair of conveyor belts and rubber components. Today the company produces a wide ranging spectrum of rubber and silicone products – from mini-components to seals weighing several kilograms. What makes the elastomers rubber and silicone so special? As industrially processed materials they display both elasticity and shape retention.

Elastomer solutions from HÜBNER are used in different industries around the world. For railway vehicles and other vehicles, the company produces window sealing systems, door profiles and finger protection profiles with integrated sensors. Products in the medical technology sector include silicone membranes for dialysis machines. Our products for the oil industry are particularly robust – they can withstand the extreme weather conditions in offshore settings as well as high pressure applications and contact with oil.

HÜBNER also has many years of experience in the defense technology sector. The company produces diving seals and other rubber products that are resistant to chemical and biological agents. Docking fenders and rub strakes for boats are also part of the product portfolio. HÜBNER provides individual elastomer solutions as required by the customer – manufactured as extruded, fabricated or molded parts. The company's development department has decades of experience and more than 600 recipes for rubber compounds that it brings to each new project.

The expert staff make use of the latest software such as SAP or CATIA as well as in-house toolmaking capacities. With these resources, the company produces molded and extrusions parts, injection-molded corners, rubber-metal and silicone-metal bonded components all in the highest quality. A full range of standard material testing – including for fire-safety requirements – is conducted in the company's own research laboratories by highly trained specialists.

Entdecken Sie unser Portfolio für die Bereiche Industry und Rail & Bus.

Insulating materials

Extensive experience

for superior innovation

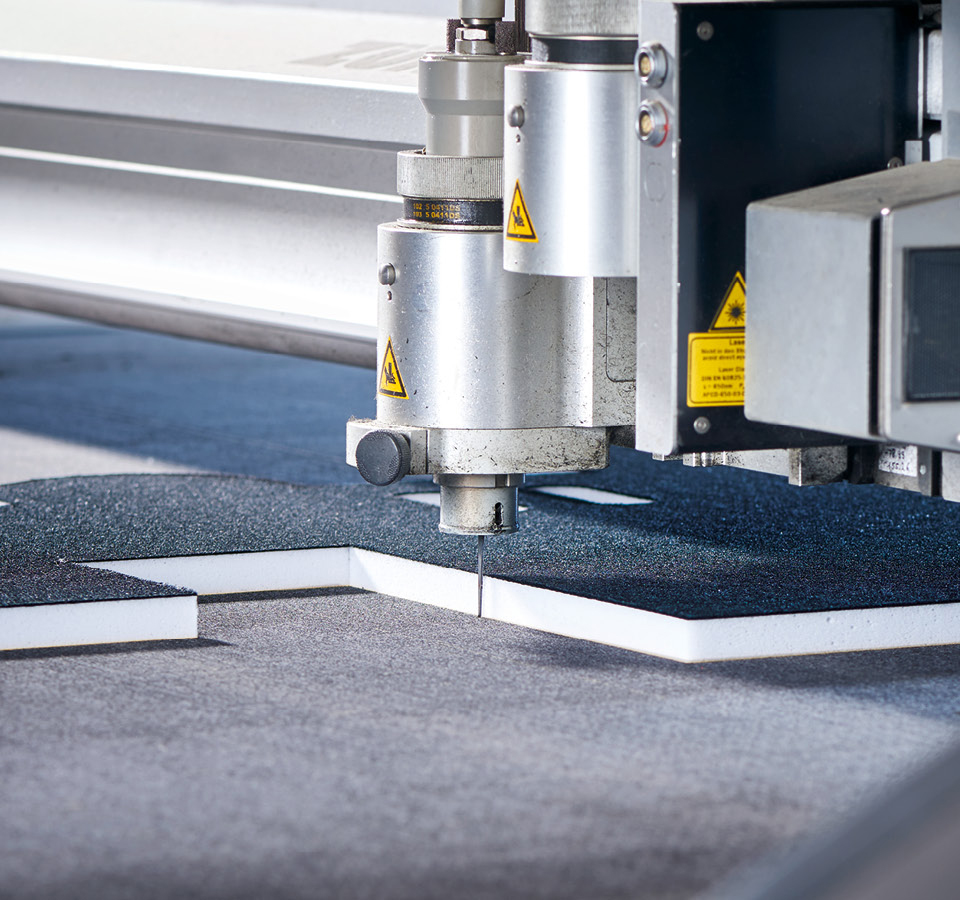

HÜBNER has advanced expertise in the development and production of soundproofing and insulation materials. The HÜBNER company Plastocell has been developing insulating materials for buses, trains, buildings and industrial applications for more than 30 years. These materials are highly effective in absorbing disturbing environmental influences and insulating against unwanted noise, helping to reduce acoustic, thermal and mechanical loads.

Our modern machinery and our experienced team of experts allow us to develop solutions that are customized to individual customers' requirements. The wide range of services includes lamination, customized parts, commissioning as well as profile cuts. Whether for touring coaches, railway vehicles, technical trade, air conditioning and ventilation systems, construction machinery, computer hardware, shipbuilding, metal processing or medical devices – our products absorb noise in a wide range of applications and provides users a better quality of life.

Find out more about insulation and soundproofing at HÜBNER.

HÜBNER has advanced expertise in the development and production of soundproofing and insulation materials. The HÜBNER company Plastocell has been developing insulating materials for buses, trains, buildings and industrial applications for more than 30 years. These materials are highly effective in absorbing disturbing environmental influences and insulating against unwanted noise, helping to reduce acoustic, thermal and mechanical loads.

Our modern machinery and our experienced team of experts allow us to develop solutions that are customized to individual customers' requirements.

The wide range of services includes lamination, customized parts, commissioning as well as profile cuts. Whether for touring coaches, railway vehicles, technical trade, air conditioning and ventilation systems, construction machinery, computer hardware, shipbuilding, metal processing or medical devices – our products absorb noise in a wide range of applications and provides users a better quality of life.

Find out more about insulation and soundproofing at HÜBNER.

One of the strengths of the company PolymerTechnik Ortrand (PTO) which HÜBNER acquired in 2006 is the wide range of materials it can process. It can handle all of the elastomers available on the market including silicone rubber as well as standard fabric types such as polyamide, polyester, cotton, felt and fleece.

In the production process, the elastomers are brought into a liquid form and then the fabrics are coated either through impregnation or brush application. Another processing method is solvent-free coating of fabrics with rubber compounds.

The material thickness can be adjusted as required by the customer as can the surface structure through vulcanization.

Elastomer-coated fabrics from the HÜBNER Group are not only mechanically robust, they also are highly resistant against UV light and other environmental factors. In addition, they provide high flame resistance. This makes them indispensable – particularly for applications with high fire-safety and general safety requirements, for example in buses and railway vehicles. For just this reason, HÜBNER uses materials in its own folding bellows production that are mainly produced from its own group company.

One of the strengths of the company PolymerTechnik Ortrand (PTO) which HÜBNER acquired in 2006 is the wide range of materials it can process. It can handle all of the elastomers available on the market including silicone rubber as well as standard fabric types such as polyamide, polyester, cotton, felt and fleece.

In the production process, the elastomers are brought into a liquid form and then the fabrics are coated either through impregnation or brush application. Another processing method is solvent-free coating of fabrics with rubber compounds.

The material thickness can be adjusted as required by the customer as can the surface structure through vulcanization.

Elastomer-coated fabrics from the HÜBNER Group are not only mechanically robust, they also are highly resistant against UV light and other environmental factors. In addition, they provide high flame resistance. This makes them indispensable – particularly for applications with high fire-safety and general safety requirements, for example in buses and railway vehicles. For just this reason, HÜBNER uses materials in its own folding bellows production that are mainly produced from its own group company.

Working with the material polyurethane has been an important part of HÜBNER's production activities for decades. And the innovative characteristics of this material continue to be of great value to customers. Whether polyurethane is processed to be soft, highly resistant or flexible, it has successfully demonstrated its versatility over the past decades in all industrial areas.

On the basis of these manifold material characteristics, HÜBNER produces products that can fulfill many special requirements. The company has its own development department to prepare special high-grade formulations for individual customer wishes. HÜBNER products are used in applications ranging from the cushioning on operating tables to the bumpers on vehicles. Polyurethane's robust structure and outstanding durability make it particularly popular with customers – together with its very pleasing look and feel. In addition, we can supply polyurethane products painted or varnished as required.

In the transport segment, the company has extensive experience in the development of passive safety elements. These individual parts and complete systems

incorporate passive pedestrian protection into modern vehicle design. HÜBNER has made a name for itself over the years particularly in the rail transport sector as a specialist for flame retardant products made of polyurethane as well as for reaction injection molding (RIM) foams.

Discover our Material Solutions for rail and bus applications.

Polyurethan

Consistency in diversity

Working with the material polyurethane has been an important part of HÜBNER's production activities for decades. And the innovative characteristics of this material continue to be of great value to customers. Whether polyurethane is processed to be soft, highly resistant or flexible, it has successfully demonstrated its versatility over the past decades in all industrial areas.

On the basis of these manifold material characteristics, HÜBNER produces products that can fulfill many special requirements. The company has its own development department to prepare special high-grade formulations for individual customer wishes. HÜBNER products are used in applications ranging from the cushioning on operating tables to the bumpers on vehicles. Polyurethane's robust structure and outstanding durability make it particularly popular with customers – together with its very pleasing look and feel. In addition, we can supply polyurethane products painted or varnished as required.

In the transport segment, the company has extensive experience in the development of passive safety elements. The individual parts and complete systems incorporate passive pedestrian protection into modern vehicle design. HÜBNER has made a name for itself over the years particularly in the rail transport sector as a specialist for flame retardant products made of polyurethane as well as for reaction injection molding (RIM) foams.

Discover our Material Solutions for rail and bus applications.