Thermoplastic polymers are known for their versatility, recyclability and formability when heated. They can be configured precisely and economically into complex forms – perfect for the production of highly functional, optically appealing components in nearly all industries. Thermoplastic injection molding provides a highly effective method for producing technical components with a wide range of characteristics and high repeatability.

Solutions tailored to customer requirements

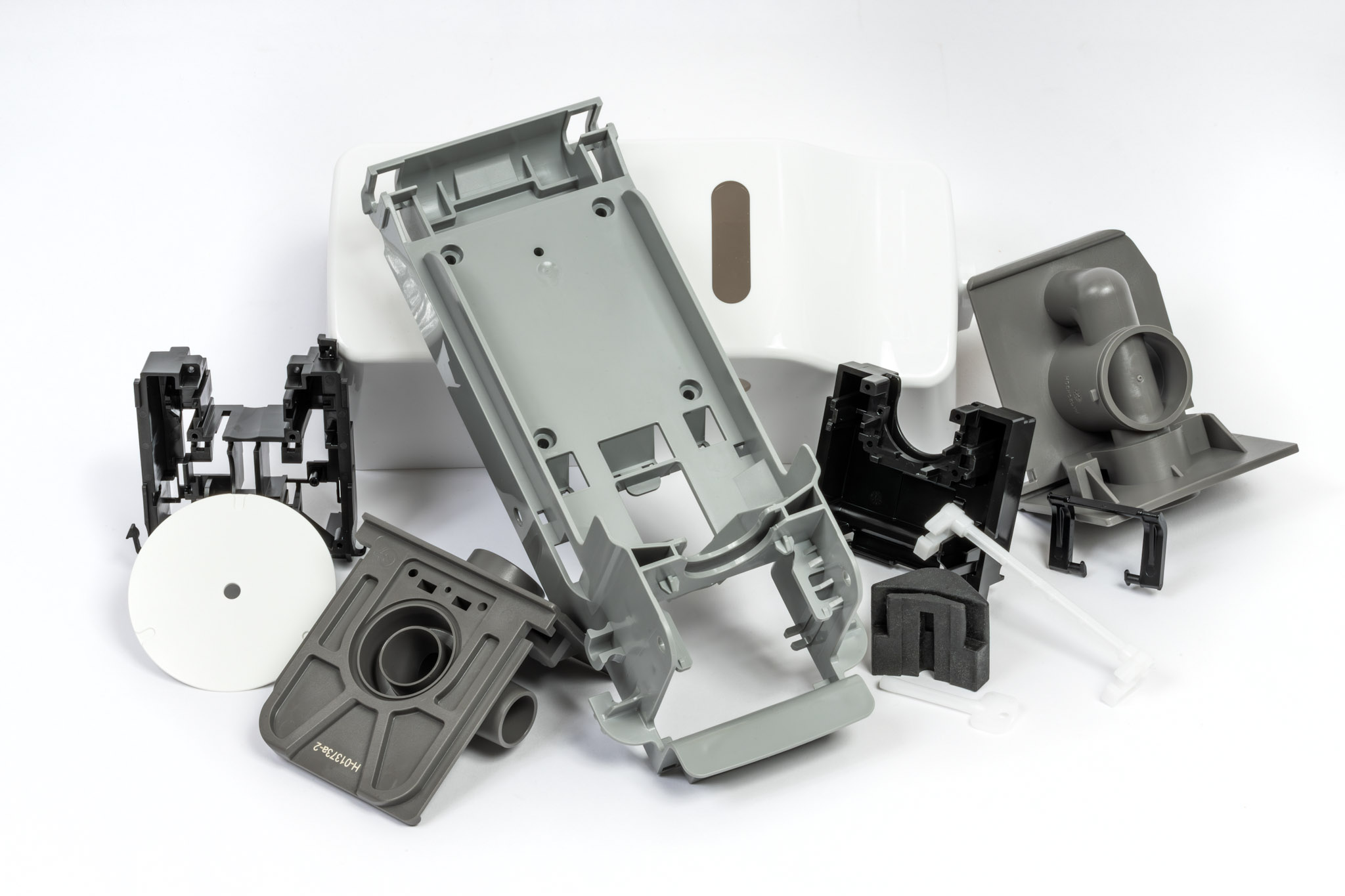

For decades at HÜBNER, we have been developing and delivering complex, individual solutions in the field of thermoplastic injection molding – serving our customers with the manufacture of single components and complete products. From individual parts to large series. Whether it’s inserts, multi-component solutions or customized requirements for haptics and design: our thermoplastic solutions meet the highest standards in appearance, functionality, and durability.

With these capabilities we are able to meet a wide range of requirements from our customers:

- High dimensional accuracy and repeatability

- Mechanical, optical and chemical characteristics as required

- Multiple variants through the use of inserts, multi-component technology or customized surface finishing

- Resistance to temperature, chemicals and UV radiation

- Material options range from standard plastics to engineering plastics and high-performance polymers

Our service portfolio for

thermoplastic Injection molding

Our service portfolio for thermoplastic Injection molding

Thanks to our in-house development department, on-site toolmaking and extensive series manufacturing experience, we can guarantee high quality thermoplastic services on an economical and highly reliable basis.

With our close and ongoing collaboration with the plastics and technology centers of leading machine and equipment manufacturers, we are continually optimizing our production processes in line with the latest technological standards for future-proof manufacturing. We combine state-of-the-art manufacturing technologies with a broad portfolio of services that can be flexibly adjusted to meet your project requirements.

The HÜBNER portfolio of services includes:

- Design, development and prototyping

- Pre-production and series production (small, medium, and large series)

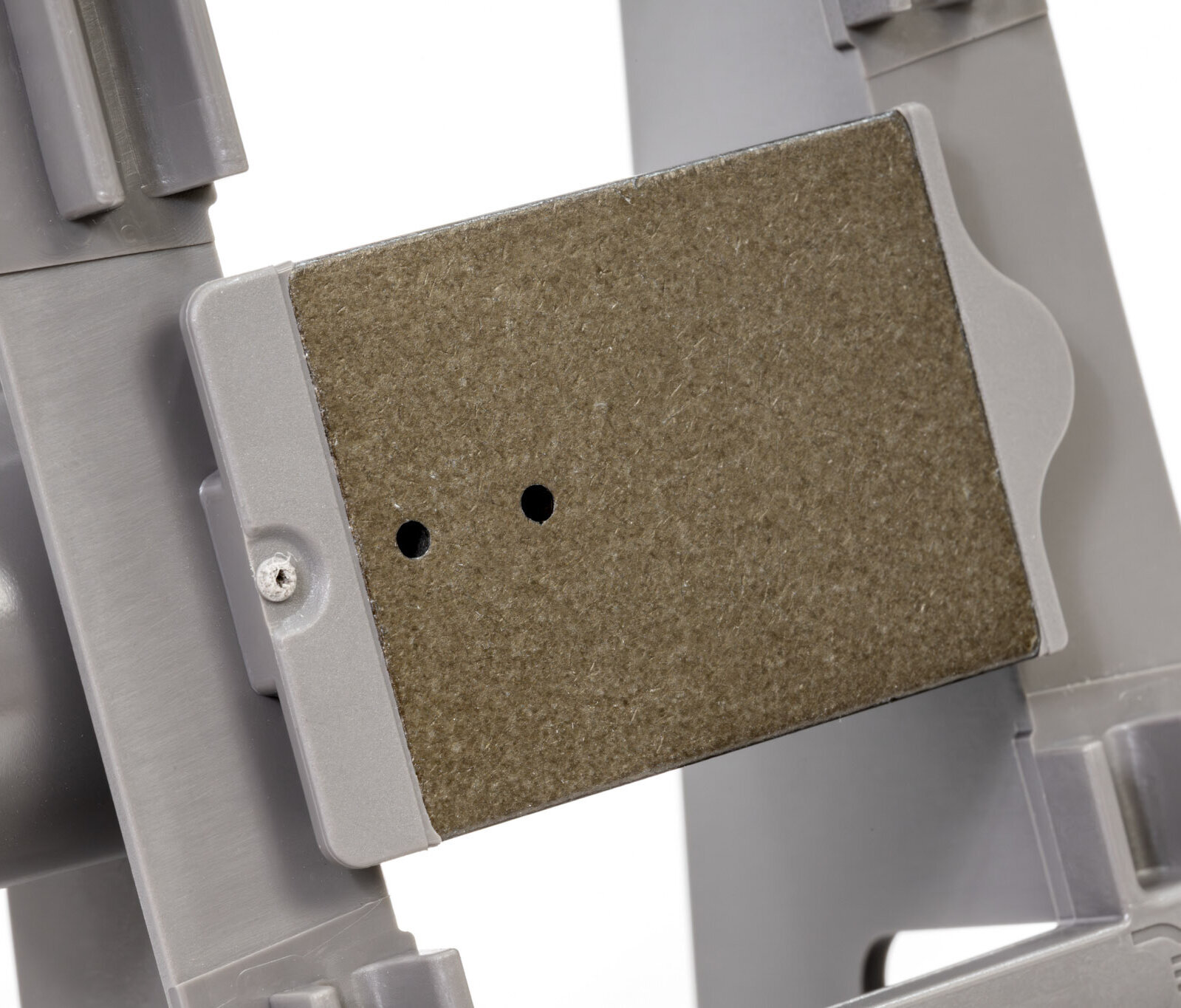

- Single and multi-component injection molding with and without inserts

- Component assembly, ultrasonic welding, printing, laser marking, surface finishing

- Clean and cleanroom assembly

- 100% testing and complete product manufacturing including final packaging

Processing capability for

many thermoplastic materials

We process and work with a wide range of thermoplastic materials:

- Standard plastics: HDPE, LDPE, LLDPE, PP, ABS, …

- Engineering plastics: ABS, POM, PC, PMMA, PA6, PA6.6, PA12, PBT, PPO, SAN, TPE, TPU, polymer blends, …

- High-performance plastics: PA12, PEEK, …

On this basis, we deliver standard, technical and high-temperature-resistant thermoplastic parts, disposable pumps, single and multi-use inserts, manual or contactless dosing systems, among many other products and components.

Clean and low-particle

plastic assembly production in accordance

with the highest quality standards

We have a special focus and expertise in clean, hygienic manufacturing. With our Class 7 and Class 8 cleanroom assembly facilities, we provide the highest quality standards for sensitive applications. Supplying components under clean-packed conditions ensures especially low particle and bioburden levels.

For the highest standards of purity and sterility, our plastic components can also be sterilized, for example for medical applications with direct patient contact. This ensures safety even in highly sensitive fields.

We aim to serve our customers in close cooperation by developing economical solutions that perfectly fulfill all technical requirements – from initial concept development to series product to delivery of the packaged end product.

Tino Truppel

Head of Regional Sales Health,

Industry & Advanced Sectors

Division Material Solutions

Tel. +49 561 998 1341

Tino.Truppel(@)hubner-group.com

Jan-Johannes Roloff

Product Development Engineer Health,

Industry & Advanced Sectors

Division Material Solutions

Tel. +49 561 998 1406

Jan-Johannes.Roloff(@)hubner-group.com