Prototype production, model construction and mold making

The economical fiber composite FRP (fiber-reinforced plastic) can be used for many applications and is characterized by a high degree of strength and stability. Its non-susceptibility to corrosion is also a significant benefit for use in the mobility sector.

We can provide product development, prototype and sample construction, mold and model making as well as the production and assembly of ready-to-install components. We are able to produce complex component configurations and shapes in accordance with individual customer requirements. Also available as part of our comprehensive service is the production of spare parts as well as the repair of defective products from other manufacturers.

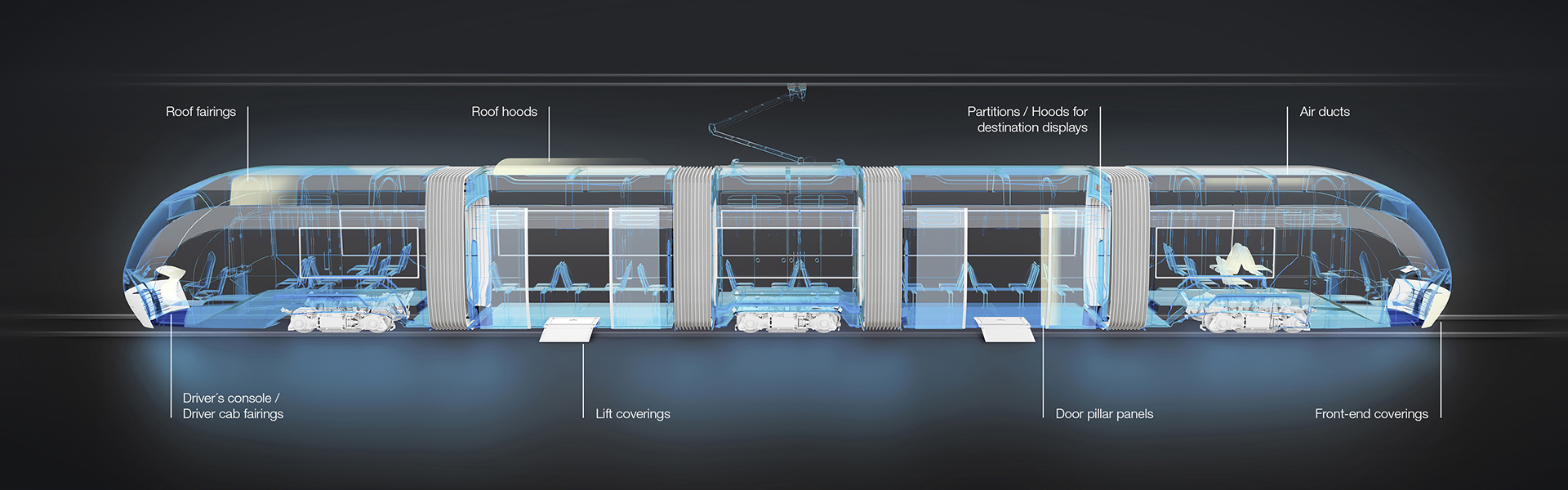

Areas of application for buses and trains

We supply both German and international railway vehicle manufacturers with high quality paneling systems made of fiber-reinforced plastic. FRP components are used, for example, in roof constructions in hybrid and CNG buses as well as for vehicle front and rear ends.

Our interior paneling elements made of FRP are used, for example in the locomotive cab of the Deutsche Bahn's ICE 4 trains. For this new prestige order, the FRP blanks are initially produced in a manual laminating process. In the completion of the units, various other metal parts, rubber profiles and insulation elements are added together with connecting pieces made of metal, rubber or insulation material. During the subsequent assembly of the components, heating elements, passenger counting sensors and light sensors are premounted.

You can find more information about our mould making on the website of the HÜBNER group company GWP.

For trams and tractors

The HÜBNER Group company GWU produces individual vehicle paneling systems and sound insulation components, including tram front-ends as well as components and systems for tractors, excavators and buses. GWU provides its customers with a comprehensive range of services – from product development, to prototypes and sample construction, to mold and model making, to prdouction and assembly.

Certified quality

For quality and process control, all of the production steps as well as all of the basic materials used in the processes are fully documented. We also work with a fully integrated quality management system that is certified in accordance with ISO 9001:2015.

In addition, we are certified in accordance with the environmental management system ISO 14001:2015 through extensive ecological and sustainability measures.

The changeover from the existing fire safety standard DIN 5510 to the EN 45545 standard has raised the requirements for fire safety characteristics enormously throughout Europe. The raw materials that we use fulfill these standards up to the designated Hazard Level 3, which meets the highest safety requirements.

Ralf Schmidt

Vertrieb Material Solutions für Rail & Bus

Tel. +49 561 998 1169

Ralf.Schmidt(@)hubner-group.com