In virtually any color or shape

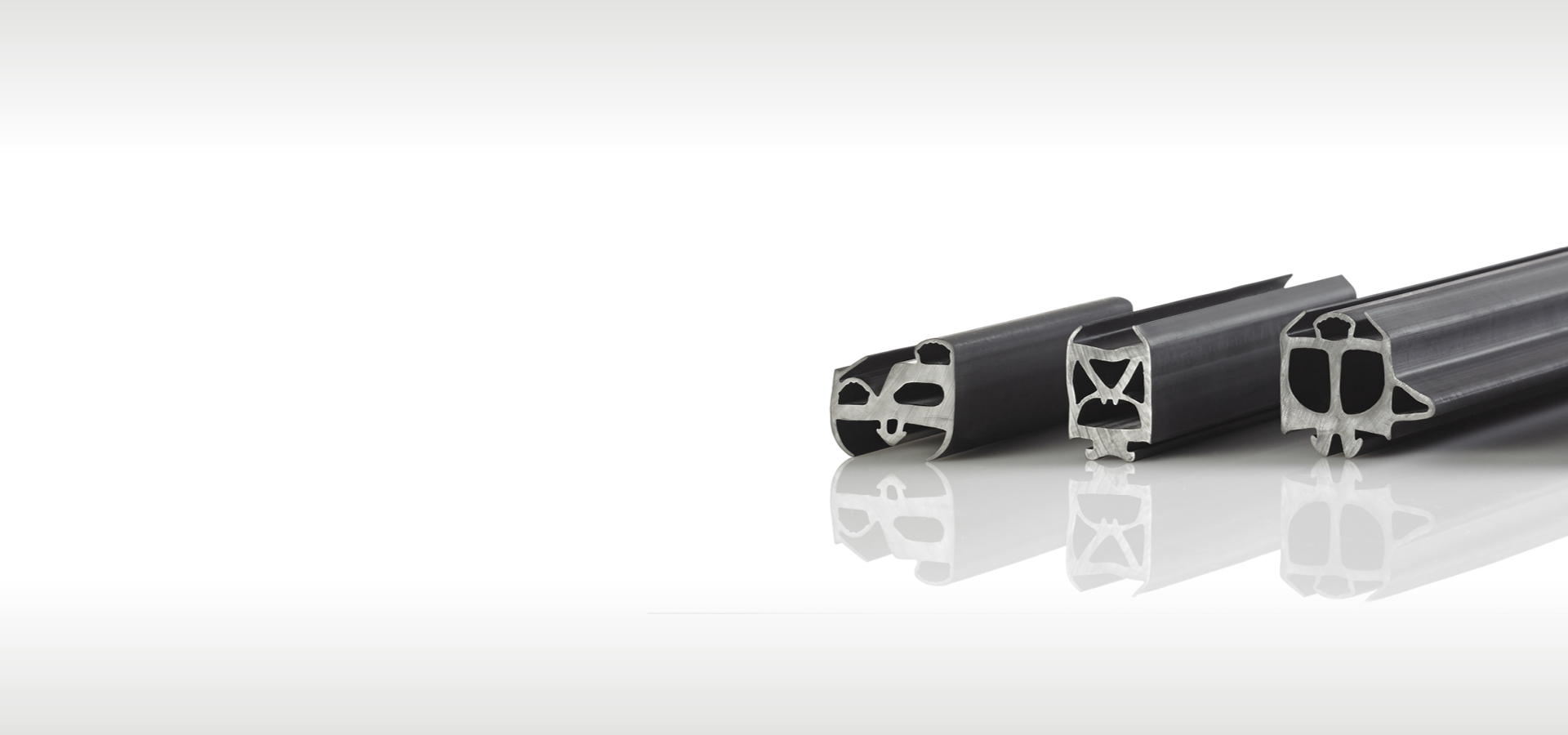

HÜBNER is specialized in providing high-quality molded parts and profile seals. These in-house developed components can cover the full range of special requirements. They are produced using our in-house proprietary compound recipes.

The components are oil, heat and UV resistant and can be provided in virtually any color, shape or configuration. For applications requiring special levels of elasticity and resistance to cold and heat or particular electrical insulation properties, high-quality EPDM synthetic rubber or silicone can serve as a good basic material.

- We do injection molding in a wide range of shapes and sizes – from 10 g to 5 kg, with a maximum length of 2 meters.

Single component or multi-component processing for more flexibility

We manufacture rubber elements with single or multi-component processing. The multi-component process is used when various parts of the seal need to have different characteristics. This is the case, for example, when the foot of a seal needs to be mounted in a track and should therefore be harder than the softer sealing lip.

Characteristics of HÜBNER rubber and silicone

- They are resistant against heat, cold and UV radiation.

- In addition they meet all relevant fire safety standards.

- Of course, we can also produce them to be especially oil and lubricant- resistant as well.

Applications for HÜBNER molded parts

Our molded parts made of rubber or silicone are not only used for industrial applications or in medical technology products but also are used extensively in public transport, for example as:

- Window seals

- Window edgings

- Hatch seals

- Door and cover seals

- Finger protection profiles with electrical safety edges

- Suspension elements

- Elastic mountings to reduce damaging or disturbing vibrations

- Gap covers