Exceedingly sturdy articulation systems

for all bus types

Our articulation systems for articulated buses meet all requirements in this area. They can be installed in low-floor or in high-floor buses, have an extremely low weight and are nonetheless exceedingly sturdy. To achieve these impressive characteristics, we only make use of high-quality materials from audited suppliers.

Our articulation systems are modularly constructed – that means we can very quickly develop individual solutions for specific customer needs. Our articulation system designs are based on FEM (finite element method) calculations. Data from tests carried out under extreme conditions throughout the world underpin these calculations.

Subsequently the articulation systems are subjected to durability testing at renowned testing laboratories and universities. On this basis, we can guarantee that our articulation systems for articulated buses fulfill the highest requirements.

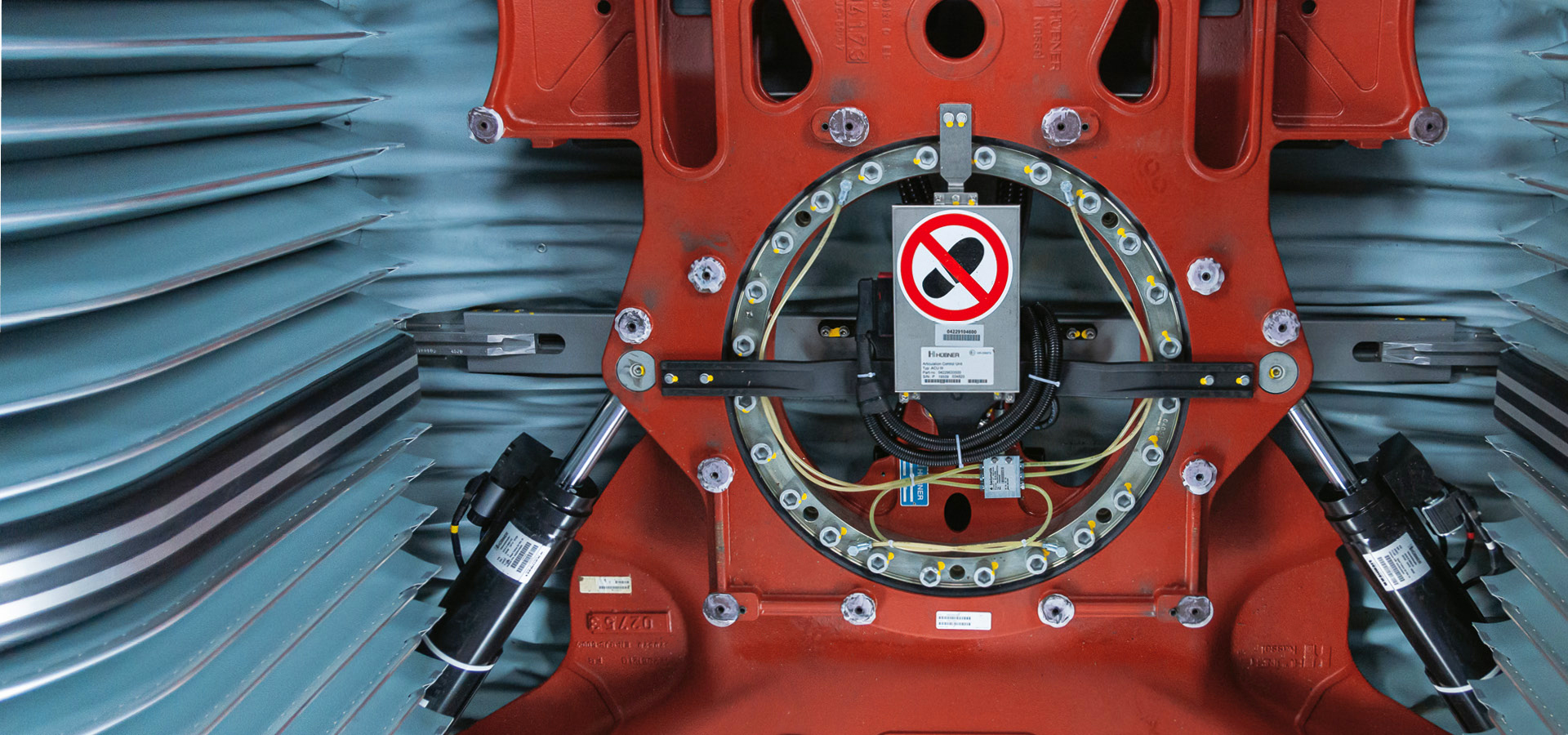

HNGK 19.5 eco and HD – The universal bus articulation

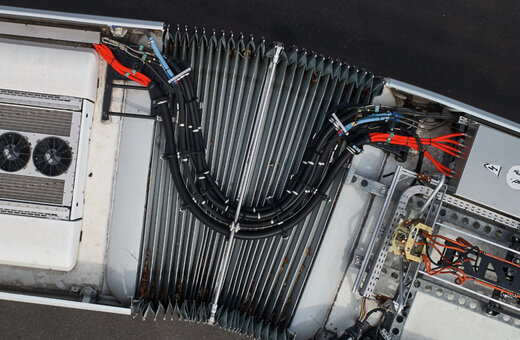

The universal articulation HNGK 19.5 eco and HD from HÜBNER are among the most frequently used articulation systems worldwide. Their simple and clearly defined connection surfaces make them favorites with bus manufacturers around the globe. With this construction the articulation can be mounted very quickly on the front or rear vehicle segments.

The main components of the system such as the bearing, the system control and the damping elements are all easily accessible via the maintenance hatch. In the event of damage, the single dampers can also be replaced individually.

Usually the universal system is delivered with an electronic control unit. This unit detects the driving situation and when necessary can intervene in critical situations. In addition, it conducts a system diagnosis for early detection of any defects. This makes it possible to minimize downtime and to keep passenger safety at a high level.

With its low weight the HNGK 19.5 eco helps to reduce bus fuel consumption. The HNGK 19.5 HD is ideal for heavy duty applications as it can stand up to exceedingly high loads and forces.

HNG 19.5 eco and HD:

- Axle load: 25 kN (eco) / 35 kN (HD)

- System weight: 590 kg (eco) / 650 kg (HD)

- Suitable for low-floor and high-floor buses

- Clearly defined connection surfaces

- High damping moment

- Elastic torsional connection

- Integrated power connection

- Available in standard or deluxe versions

HNG 15.3 – The heavy duty articulation

The heavy-duty HNG 15.3 provides the same functionality as the universal articulation systems HGNK 19.5 eco and HD, but has been specially developed for vehicles with higher axle loads. With this articulation system axle loads of up to 4.5 tons can easily be accommodated (as sometimes occurs with gas, trolley or hybrid buses, for example). This systems is used with particular frequency in North America.

HNG 15.3

- Axle load up to 4.5 tons

- System weight: 590 kg (without rear vehicle connection)

- Suitable for low-floor and high-floor buses

- Clearly defined connection surfaces

- High damping moment

- Elastic torsional connection

HNG 17.0 – The ball articulation system for puller vehicles

The ball articulation system HNG 17.0 was specially developed for puller vehicles. It is simply constructed, economical with a particularly resilient design. With the special articulation bearing all movements can be realized at single bearing point – without the use of hydraulic or mechanical damping. The ball articulation system HNG 17.0 is an ideal solution for developing markets where particularly robust articulation systems are needed. It is delivered in ready to install components.

HNG 17.0:

- For puller vehicles

- System weight: 225 kg

- Suitable for low-floor and high-floor buses

- Clearly defined connection surfaces

- Economical