HÜBNER’s gangway systems for high-speed trains deliver maximum safety, comfort and operational efficiency. They are designed to meet the most demanding mechanical andaerodynamic requirements in connecting rail cars. With modular corrugated bellows, bridge systems, fairing elements and various attachment options, HÜBNER gangway products are providing reliable inter-car connections for trains operating around the world – even at speeds exceeding 300 km per hour.

With its modular solutions, HÜBNER offers durable systems that can be readily tailored to vehicles of all types. With features ranging from single corrugated bellows to HÜBNER’s patentedfairing system, transit operators benefit from a combination of highly innovative technology, peak operational safety and reliability, and tangible energy savings.

HÜBNER’s gangway systems for high-speed trains deliver maximum safety, comfort and operational efficiency. They are designed to meet the most demanding mechanical and aerodynamic requirements in connecting rail cars. With modular corrugated bellows, bridge systems, fairing elements and various attachment options, HÜBNER gangway products are providing reliable inter-car connections for trains operating around the world – even at speeds exceeding 300 km per hour.

With its modular solutions, HÜBNER offers durable systems that can be readily tailored to vehicles of all types. With features ranging from single corrugated bellows to HÜBNER’s patented fairing system, transit operators benefit from a combination of highly innovative technology, peak operational safety and reliability, and tangible energy savings.

Product overview / System solutions

HÜBNER gangway systems for high-speed trains fulfill the highest standards and offer outstanding advantages thanks to advanced engineering and in-house manufacture of key materials.

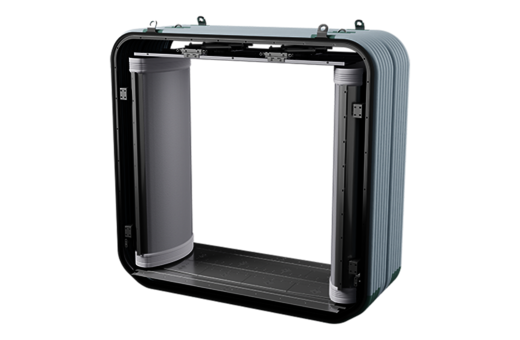

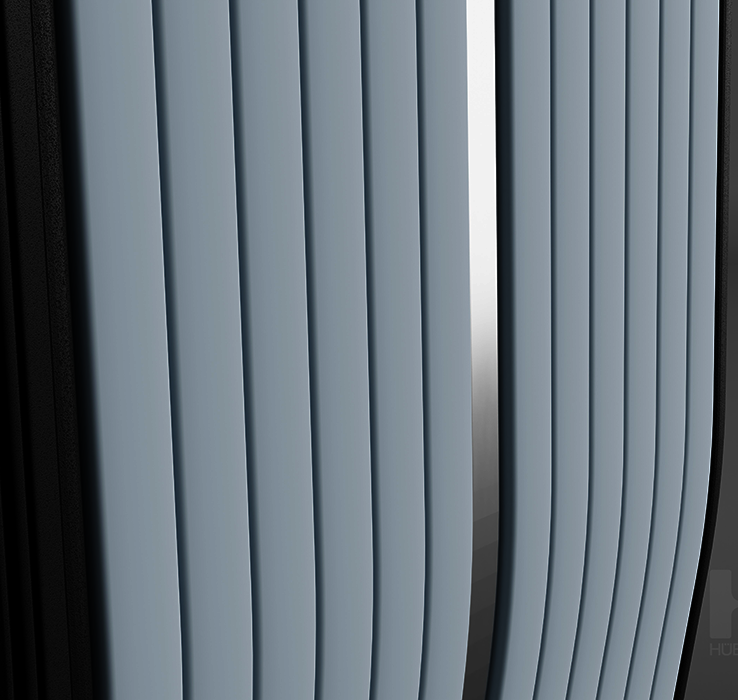

Corrugated bellows for gangway systems

Corrugated bellows serve as the central connecting element between cars. They ensure a secure, flexible and highly durable inter-car connection under varying operational conditions.

The corrugated bellows feature a high-strength design that is weather-resistant and built for long-term use in passenger service. For high-speed train applications, pressure-tight configurations are used to withstand demanding aerodynamic pressure loads.

All materials meet applicable fire-safety standards (e.g. EN 45545 HL1–HL3, NFPA 130, etc.).

Depending on the technical demands, the corrugated bellows may have a single layer (single corrugated bellows) or a double layer (double corrugated bellows).

Single corrugated bellows: Compact design, low weight, cost-efficient solution

Double corrugated bellows: For more demanding requirements in acoustic and thermal insulation

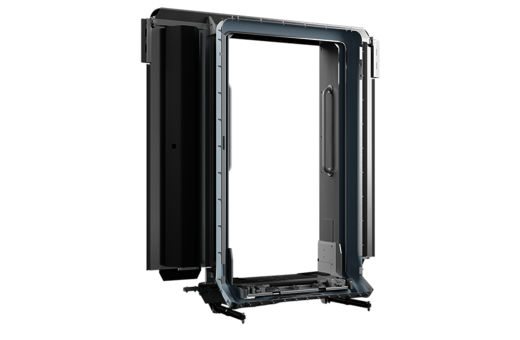

Attachment systems

The corrugated bellows may be attached to the car body either via a bolted frame or a coupling frame.

Bolted frame: A simple, robust solution for standard applications

Coupling frame: Facilitates fast disconnection or replacement; the corrugated bellows can be detached with a few manual steps

For high-speed operation, both attachment systems can be provided with integrated sealing and pressure-tight capability. Additional sealing measures are therefore not necessary during installation of the corrugated bellows.

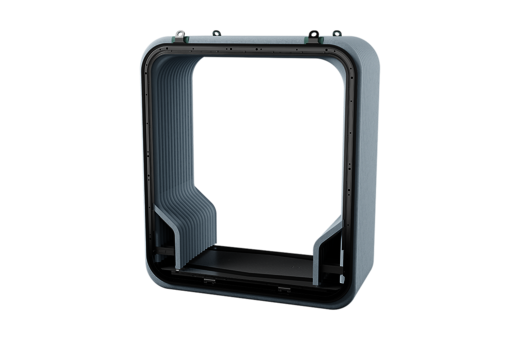

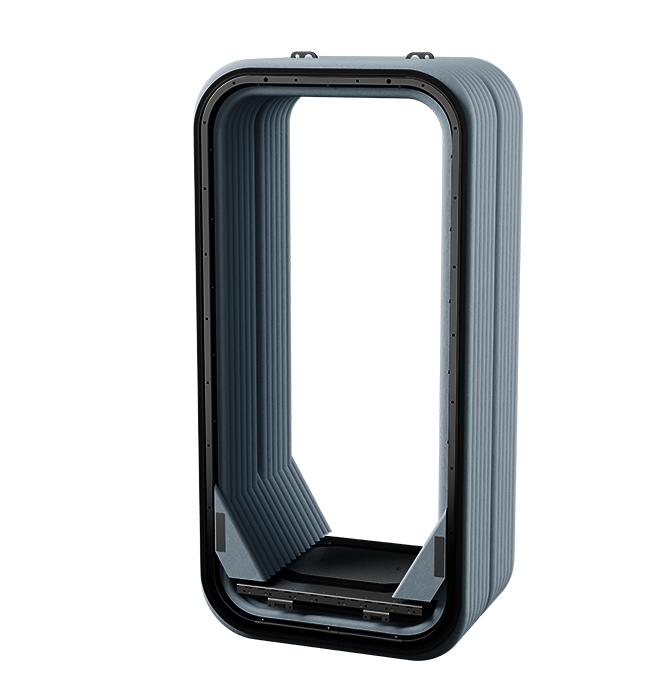

Patented HÜBNER wind fairing system

The aerodynamic fairing with its rectangular/box-shaped configuration is a proprietary design solution of the HÜBNER Group. Acting as an aerodynamic shroud, it provides a seamless connection with the car body contour and reduces air resistance. This can result in energy savings of up to 4% – an innovation that makes it possible for high-speed trains to operate more efficiently and sustainably around the world.

Product benefits & technology

Smooth, nearly flat surface: No visible seams at the corners and box-shaped bellows configuration.

Energy efficiency: The fairing reduces drag and helps to lower operating costs.

Noise reduction: Closed bellows and wind fairing systems reduce interior noise levels by up to 40 dB.

Maximilian Schäfer

Head of Sales BU Gangways | Mobility Rail

Tel. +49 561 998 1679

Maximilian.Schaefer(@)hubner-group.com