HÜBNER FrontAdd System gains important foothold in the market

“We are very pleased that we have been able to convince Stadler – as one of the leading global train manufacturers – and Norske Tog – as an innovative rail operator – of the great benefits that our HÜBNER FrontAdd System can provide. This is another important step in establishing this innovation in the market,” says Daniel Müller, responsible Key Account Manager at HÜBNER Kassel.

In this first order, HÜBNER will initially supply 34 FrontAdd Systems to Stadler for the front and rear ends of 17 vehicles. The order includes the option of up to 200 additional systems for 100 trains. In addition, HÜBNER will be supplying approximately 2600 rubber profiles for the window frames in the FLIRT Nordic Express trains starting in autumn 2025.

Greater durability and improved aerodynamics

The HÜBNER Group presented the FrontAdd System for the first time at InnoTrans in September 2024, arousing widespread interest in the rail industry. “This innovative system that simultaneously provides greater durability and improved aerodynamics supports our customers in increasing the availability of their trains while at the same time saving important resources and costs,” emphasizes Timm Kohberger, Head of Gangway Systems at HÜBNER Kassel.

The system reduces air resistance by approximately three percent, thereby contributing to more energy-efficient train operation. In this way, the FrontAdd System allows for a reduction in energy consumption of around two percent, with a corresponding effect on CO2 emissions. At the same time, it provides improved sound insulation, which reduces noise levels for train personnel in the cockpit. Field tests are planned with Stadler to further document these positive effects.

Combining high performance and sustainability

“In the development of our systems and products, we consider aspects of performance and sustainability together,” explains Timm Kohberger.“Our aim with HÜBNER solutions is to make it possible for our customers to optimize their ecological footprint on a sustainable basis – for high-performance rail transport that is also energy efficient.”

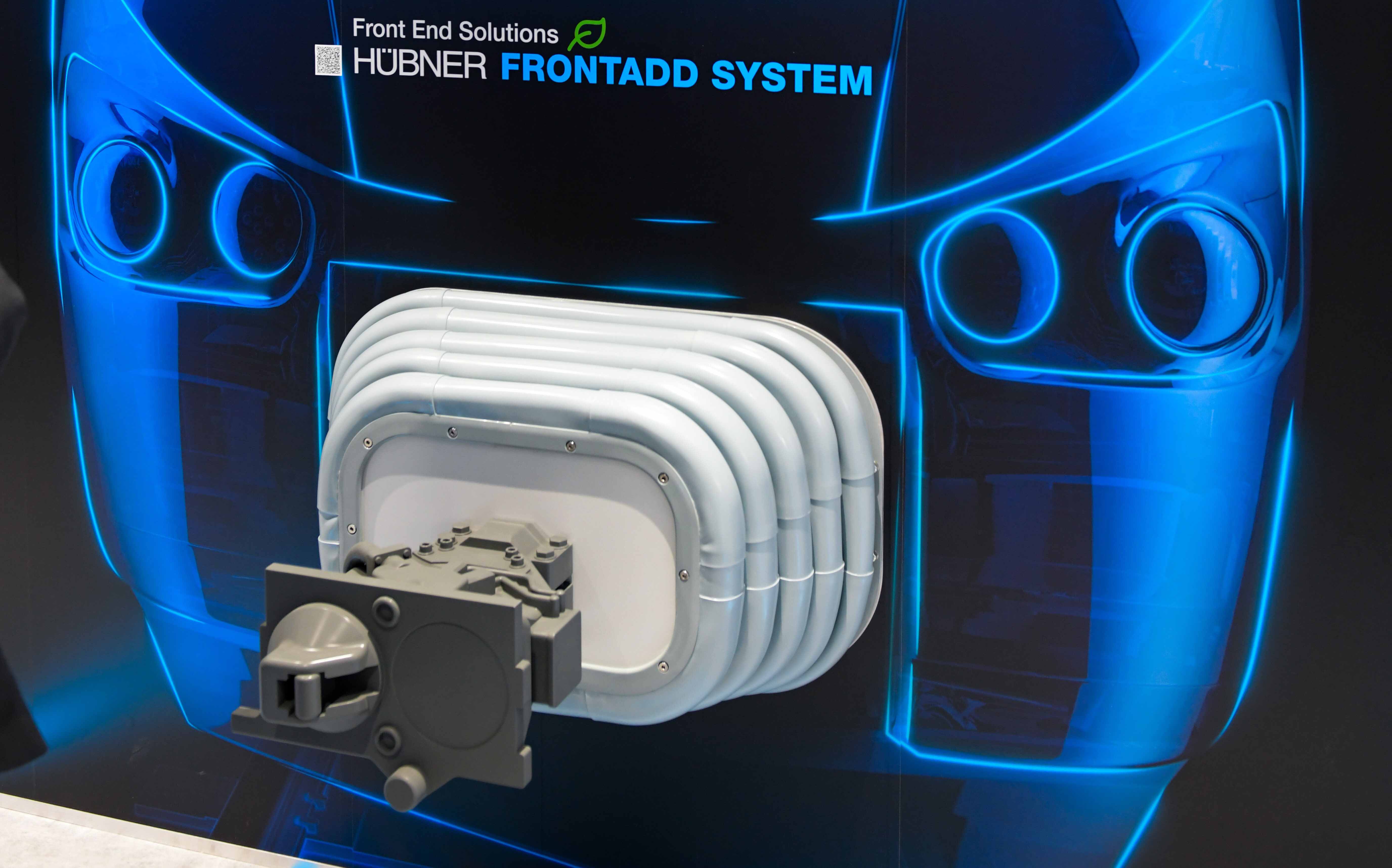

Corrugated bellows protects coupling equipment

The key element of the FrontAdd System is a corrugated bellows from the proven HÜBNER production. This is integrated around the coupling at the front end of the train and protects the sensitive technical equipment that is located there, such as cables, windshield wiper tank and motor. In addition, the FrontAdd System provides snow protection and is designed for temperatures down to minus 40 degrees Celsius. This, of course, makes it very well suited for the demands of train operation under extreme weather conditions such as occur in Norway.

“This order from Stadler underlines our role as a driver of innovation for rail transport,” points out Daniel Müller.“We deliver solutions which are individually designed for the specific challenges that our customers face, like the extreme weather conditions in Scandinavia. This way we can offer real added value for our customers and enhance trains and rail technology for the demands of daily operation.”