Thank you for your visit!

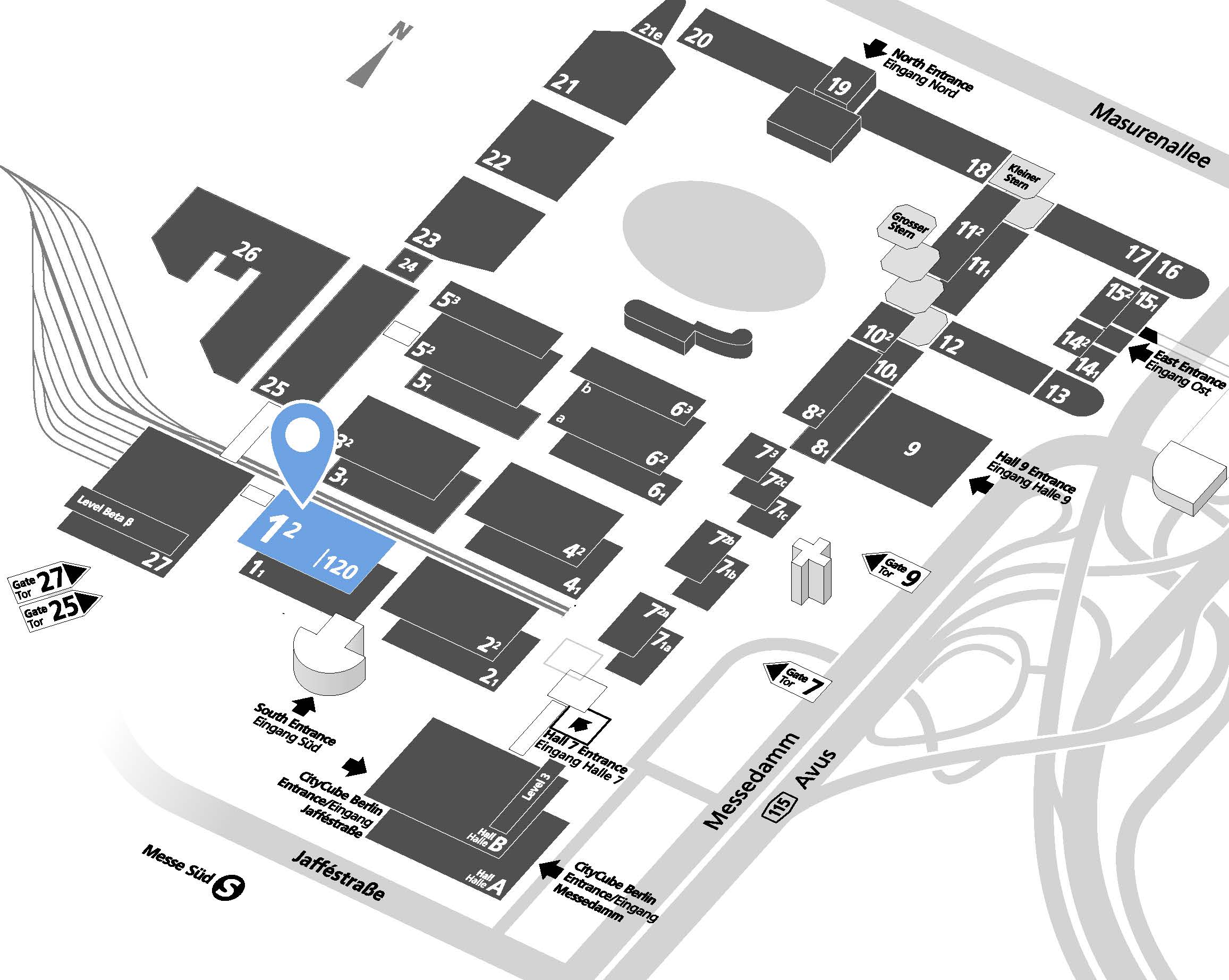

Everything about our appearance at InnoTrans 2024 in Berlin can be found here on this page.

The Original from HÜBNER

Innovative and sustainable solutions for gangway systems in all train platforms

HÜBNER’s original gangway system made its debut in the first generation of ICE trains in Germany. In the 35 years since that start, our gangways have been providing comfort, convenience and safety in high-speed trains all over the world.

Whether in the sector of high-speed, regional, metro or tram vehicles – our high sustainability standards are reflected throughout the entire product life cycle. With special refurbishment concepts, we recondition gangways for all train types to conserve resources – keeping waste products to a minimum.

In this way our customers benefit from our many years of experience joined together with our innovative strength – taking an important step so that train manufacturers and transit operators can optimize their ecological footprint together with HÜBNER.

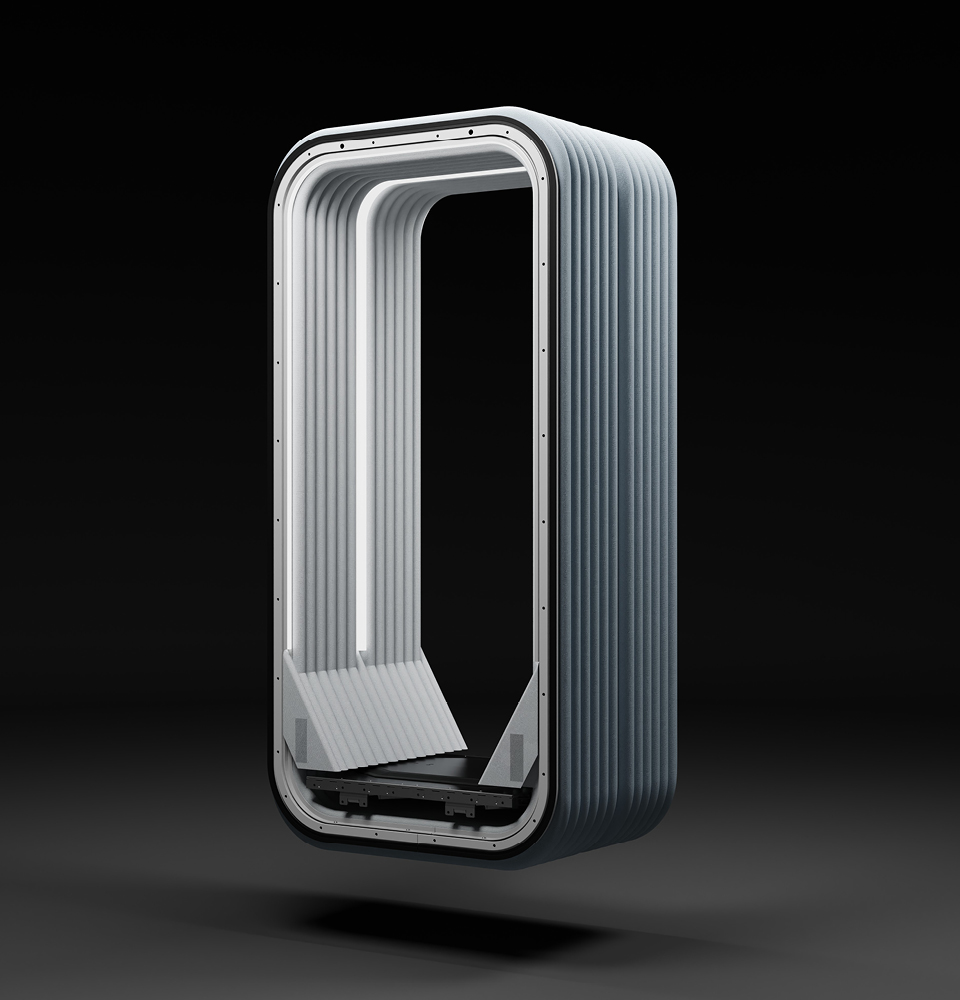

At InnoTrans 2024, HÜBNER is continuing to set new standards for gangway systems

- For the first time, we are using materials for corrugated bellows featuring recycled fishing nets and sustainable raw materials based on cellulose or viscose.

- With an extended spectrum of attractive colors and innovative design elements such as embossed materials and bright textiles, we are creating modern and inviting environments. New lighting concepts turn our gangways into places of well-being – for more comfort and a greater sense of security.

- HÜBNER’s use of innovative material and textile solutions is providing more safety – and not only in connection with fire protection. Illuminated guidance systems in the gangways direct passengers to emergency exits.

Download Center

Here you will find comprehensive information about our latest products and innovations for InnoTrans 2024 in the rail industry. Easily download brochures, technical specifications, and product data sheets to learn more about our newest developments.

Claas Michaelis

Spokes Person

Tel. +49 561 998-1710

press(@)hubner-group.com