Hydropneumatics for maximum performance

“With our chassis, we offer our customers highly comfortable and safe driving for buses, trucks, and trailers,” says Dr. Mark Wöhrmann, Managing Director of HEMSCHEIDT Fahrwerktechnik. “We achieve this noticeable improvement with our hydropneumatic technology for suspension and damping, which uses oil instead of compressed air.” The hydropneumatic components are more space-saving and energy-efficient than systems that work with compressed air, as oil has a higher energy density for power transmission in the closed hydropneumatic suspension system.

Furthermore, the hydropneumatic system ensures faster reaction times and immediate chassis response. This improves stability and increases ride comfort, also on uneven road surfaces. During heavy load changes, such as loading and unloading heavy goods, the hydropneumatic suspension and damping system quickly returns to the driving level.

Steering systems for hard-to-access areas

The experts in the HÜBNER Group are also demonstrating their decades of experience and technical innovation in steering systems. The steering systems made by V.S.E. are specially designed to reach hard-to-access areas such as loading and unloading stations more efficiently.

The compact and energy-efficient design offers customers fuel savings of up to 5% for trucks and up to 20% for trailers. In addition, vehicle productivity is increased by up to 30%, with a particularly long service life and low maintenance costs due to the elimination of mechanical connections.

Even more efficiency with Smart Steering

The V.S.E. Smart Steering electrohydraulic auxiliary steering system for controlling the trailing axle of trailers promises even greater efficiency. “With our Smart Steering, we achieve excellent maneuverability of trucks and trailers,” explains Dick Lodder, Managing Director at V.S.E. “Our customers benefit from greatly improved vehicle handling in all conceivable steering and parking maneuvers.”

The technology enables the wheels of the semi-trailer to actively support the steering process, making steering maneuvers in tight turning and parking situations more flexible. On top of that, tire wear is reduced.

Pioneer in Europe: ISO standards for hydropneumatics

These intelligent steering systems are constantly being further developed to ensure optimum coordination of all components. “Our systems are developed in accordance with ISO26262 and ISO21434 standards. This makes us the first in Europe for hydropneumatics,” says Dick Lodder. “We offer customers the system box of our steering systems, divided into up to three smaller, space-saving components. These can be installed variably in the vehicle, which greatly simplifies installation and maintenance. This turns the steering systems into a plug-and-play system.” Due to the arrangement of the components, the cable routes in the vehicle can also be shortened.

High-performance shock absorbers with maximum service life

The damping systems for commercial vehicles, which can be flexibly adapted to different areas of application and customer-specific requirements, also feature a particularly compact and lightweight design. “Our systems can be flexibly combined, for example as monotube or twin-tube dampers, constant velocity cylinders with proportional valve technology or as electrically switchable damping units,” says Rainer Eickhoff, Sales Manager at HEMSCHEIDT Fahrwerktechnik.“Reliability and driving comfort for our customers’ vehicles, coupled with stability and high energy efficiency, are our focus.”

With a focus on sustainability in production, HEMSCHEIDT Fahrwerktechnik guarantees its customers a particularly long service life for its systems. With regular servicing and maintenance, a service life of well over 30 years can be achieved.

Passive corner module for e-trucks goes into series production

As the technical requirements vary depending on the vehicle type, HEMSCHEIDT Fahrwerktechnik develops customized solutions for trucks, buses, and agricultural machinery and is, therefore, constantly innovating. “We will also start series production this year with our twin-spring damper module for an electric truck platform, in which we combine the mechanical suspension, the damper and a top-mount bearing into an integrated system for optimum user-friendliness,” explains Rainer Eickhoff.

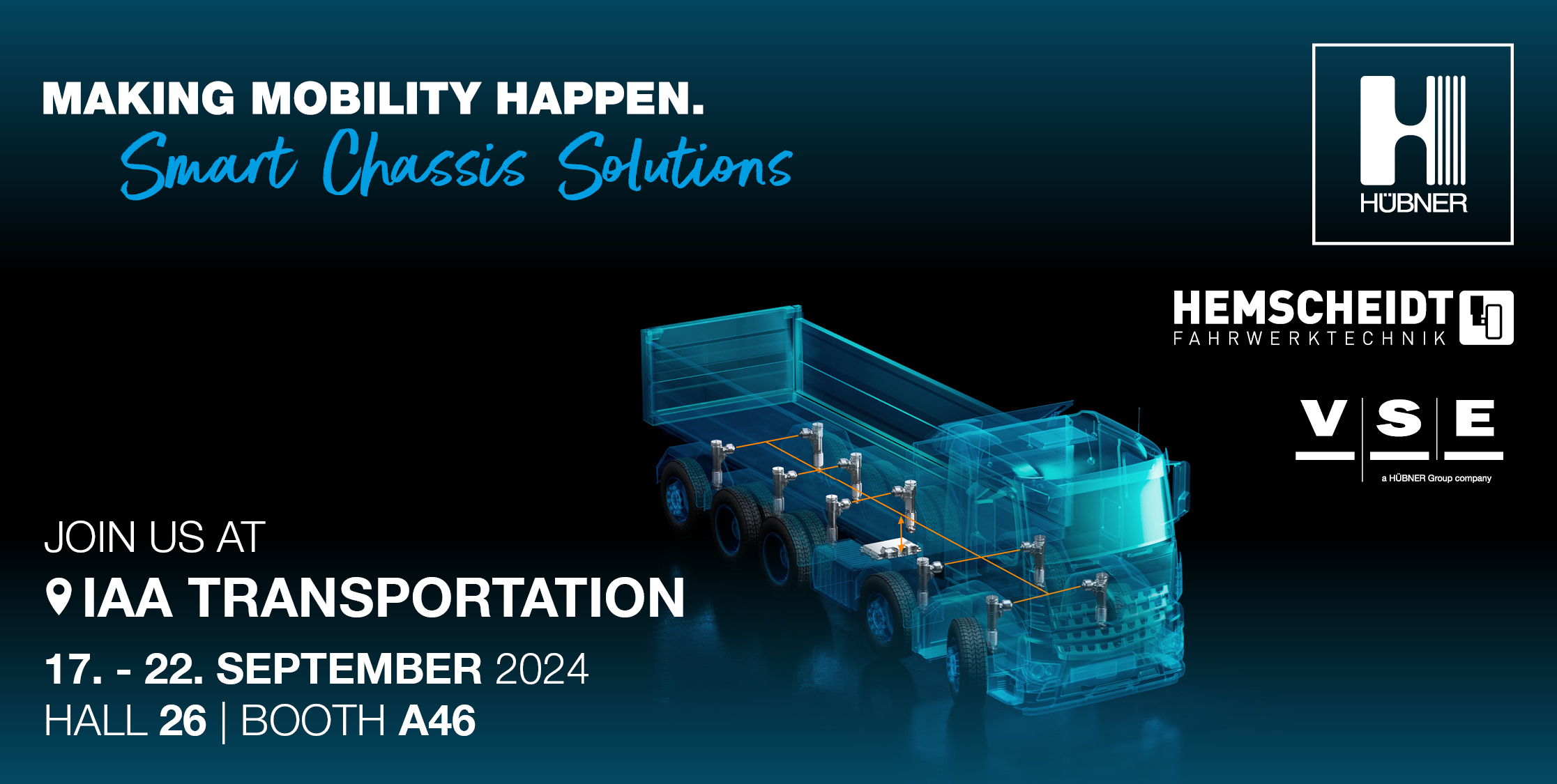

The experts from HEMSCHEIDT Fahrwerktechnik and V.S.E are looking forward to welcoming customers, trade visitors, and other interested parties at the IAA Transportation in Hall 26 / Stand A46.

More about the components and system solutions of the HÜBNER Group for commercial vehicles

HEMSCHEIDT Fahrwerktechnik

Smart Chassis Solutions

HEMSCHEIDT Fahrwerktechnik GmbH & Co. KG (HFT) is a specialist in the development and production of customized, hydropneumatic chassis systems for buses, rail and commercial vehicles. The company was founded in 1929 under the name Maschinenfabrik HEMSCHEIDT Wuppertal. Since then, it has been a highly specialized partner to the commercial vehicle industry in chassis technology. HFT has been a wholly owned subsidiary of the HÜBNER Group since 2007 and manufactures high-performance hydropneumatic suspension systems for buses, rail and commercial vehicles. HEMSCHEIDT Fahrwerktechnik is based in Haan-Gruiten near Düsseldorf and employs 53 people.

Vehicle Systems Engineering B.V. (V.S.E.)

Vehicle Systems Engineering B.V. (V.S.E.) is a specialist in advanced, innovative electro-hydraulic steering systems for rear axles and hydro-pneumatic suspension solutions for buses and commercial vehicles. V.S.E. has been well-known in the automotive world since 2001 and is based in Veenendaal near Utrecht, the Netherlands. Since 2021, the company has been a wholly owned subsidiary of HÜBNER and develops high-performance and advanced steering and suspension solutions. The systems are primarily used to enable the use of vehicles in hard-to-access areas. V.S.E. employs 70 people.